Circular economy

Circular economy

For decades, material use has driven human progress and economic growth—but at a high environmental cost. The current linear “take-make-waste” model, largely powered by fossil fuels, is unsustainable. According to The Circularity Gap Report 2024, material extraction and use account for 70% of global greenhouse gas emissions and cause over 90% of biodiversity loss and water stress, threatening the planet’s life-support systems.

The Circular Economy offers a transformative solution. By rethinking how we produce, consume, and reuse resources, it supports the energy transition, reduces environmental impacts, and safeguards the well-being of current and future generations.

Embracing circularity is essential to respect planetary boundaries while building a resilient and sustainable economy.

At EDP, the Circular Economy approach is extended beyond our activities, and throughout the value chain, contributing to the reduction of greenhouse gas emissions.

For us, this is the right way forward.

Our commitment

total waste recovered along the assest's life cycle

The circular economy strategy

Our Circular Economy Strategy is built on the principles of reducing, optimizing, and recovering resources throughout our operations. The strategy emphasizes the efficient use of natural resources and integrates circular design into the business model to minimize material extraction and consumption, while enhancing waste recovery and promoting material reuse across our value chain.

Content card grid

EDP’s seven axes of action to accomplish a circular economy

Promote the reduction of inputs of resources and materials and reduction of waste outputs.

Promote solutions that extend the product lifecycle, including modular design solutions.

Integrate digital solutions that allow dematerializing processes and reducing the consumption of materials and resources

Promote the valorization of waste materials at the end of life, creating symbiosis with other sectors of activity.

Promote business models with various circularity levels in products/services, like life cycle extension and efficiency.

Promote circularity practices: replacing materials, recycled, reused: identifying circularity’s labells.

Ensure the company's responsibility for its products/materials. Influence the value chain to enhance circularity.

Through these circularity initiatives, we transform ambition into action – driving change that benefits people, the planet, and the economy.

Close The Loop Partnerships

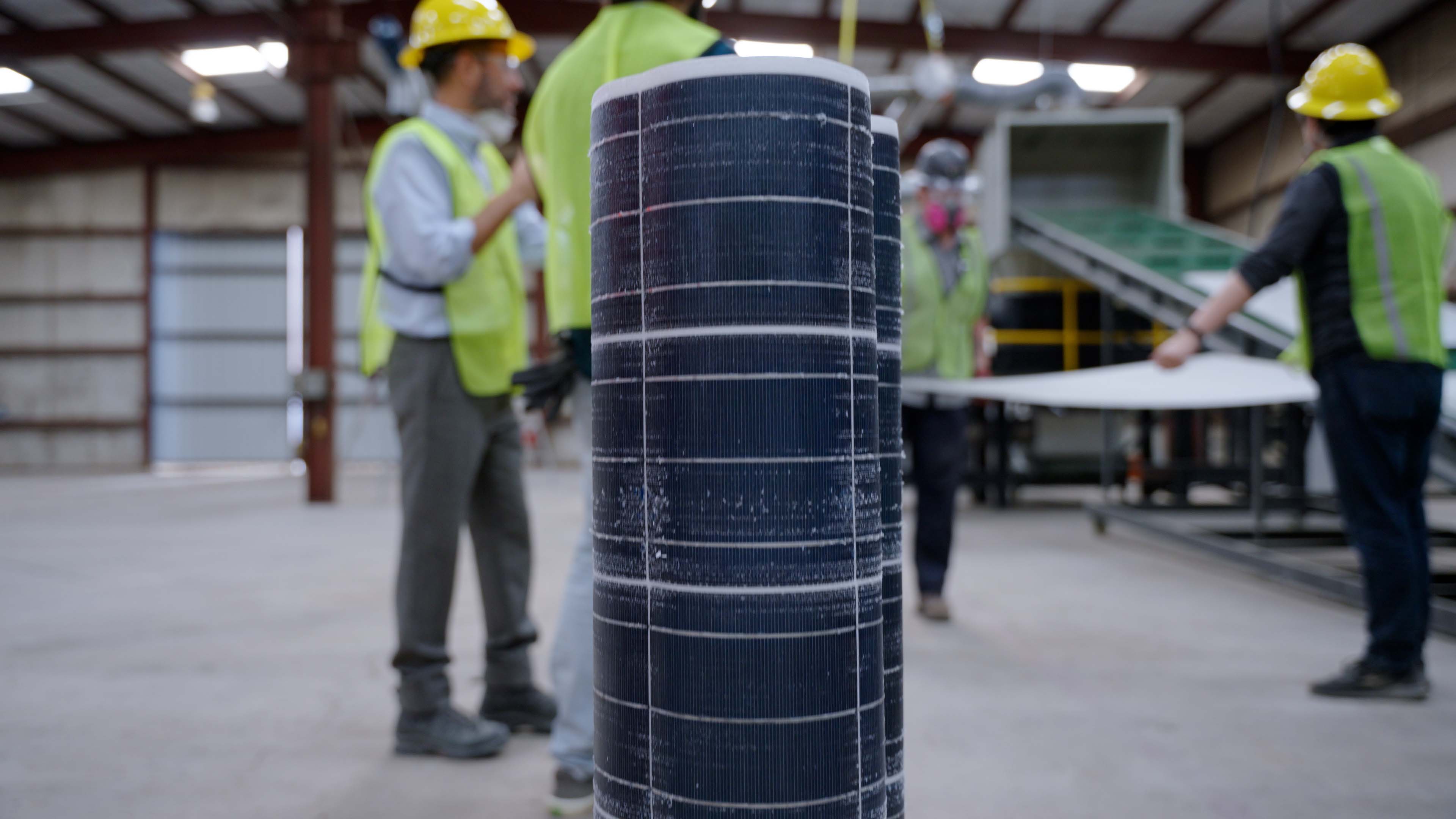

EDP launched the Close the Loop Program, emphasizing partnership with recyclers like SOLARCYCLE and over 20 other materials recyclers across North America.

This initiative underscores EDP's commitment to sustainable practices, aiming to efficiently use resources and extend product lifecycles. By fostering a circular economy, EDP seeks to support the advancement of renewable energy supply chains and meet ambitious ESG targets.

Through collaboration with leading recyclers, the Close the Loop Program ensures proper recycling of materials while adhering to stringent environmental standards. This also helps support the advancement of US renewable energy supply chains tied to a vibrant secondary market for recycled materials through the establishment of partnerships and preferred pricing.

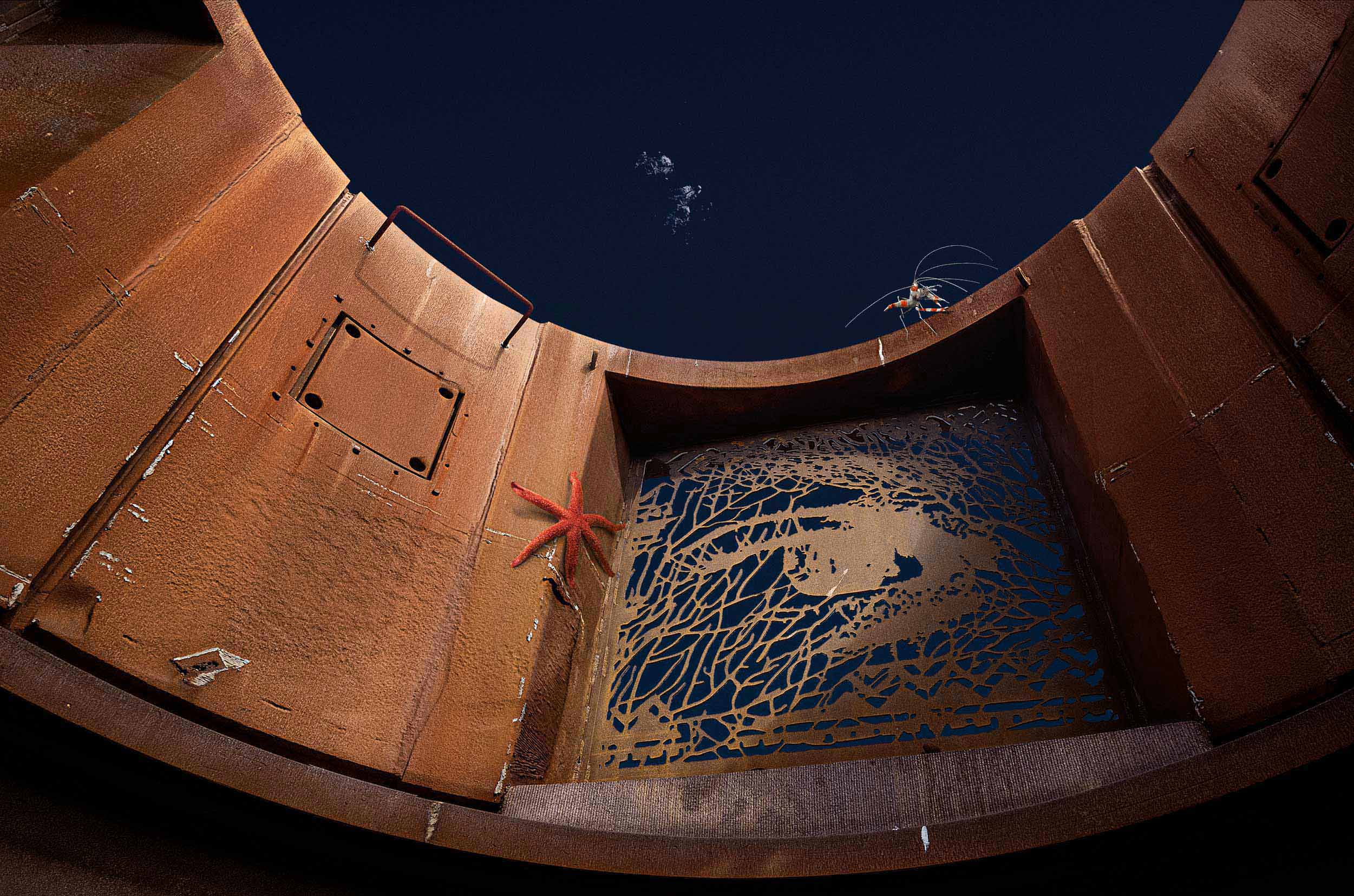

Recovery of wind turbine blades & solar panels

One of the most important challenges for the renewable business is waste generation, especially wind turbine blades and solar panels.

In this regard, it is important to search for opportunities to promote innovative solutions for the recovery of end-of-life wind turbine blades or solar panels. EDP does this by analyzing potential collaborations, participations or partnerships regarding innovative solutions and implement new circular alternatives identified.

This helps avoid the landfill of blades and panels and gives them a second life by applying a transformation process that allows them to be put back into the cycle.

ReCircular: Manual for coal power plants decommissioning

EDP has made significant progress in phasing out coal in recent years and identified the need to set a framework to guide the decommissioning processes of coal power plants.

This framework aims to support the decommissioning processes of coal power plants or other types, to make these processes more circular, systematizing a set of best practices to be followed, accompanied, whenever possible, by metrics to support the management of the process.

The manual also identifies the axes of circularity to which the best practices contribute, and serves as a tool for raising awareness and passing on knowledge.

Integration of cork in a floating solar plant

EDP has integrated cork composites in the floaters of the solar photovoltaic Alqueva project.

The introduction of cork composites, instead of conventional virgin plastic, enabled a partial substitution of non-renewable material with a local and natural one, while also reducing environmental impact of transport.

Cork composites work as a carbon sink, abating part of the GHG emissions from the non-renewable materials used, and more favourable at biodiversity level. As part of the project, a life cycle analysis (LCA) was conducted to specifically assess the impact of these types of floating photovoltaic projects versus projects using conventional floaters.

Reconditioning power transformers

Analytics4Assets – Advanced Asset Management Tool, is an example of the contribution of digitalization to circularity in EDP’s electricity networks, through artificial intelligence. The analysis of the network's technical assets, like HV/MV power transformers, HV circuit breakers and HV powerlines, allows to obtain advance knowledge about their behaviour throughout their life cycle and provides relevant support for optimizing maintenance and investment plans.

The Health Engine - Power Transformers, an Iberian digital transformation project, uses advanced analytics to build a data-driven management and maintenance strategy for Generation transformers.

The information produced in both tools is used in power transformers merit analysis and is helpful to decide whether the equipment should be conserved, improved or rehabilitated.

Incorporating new components and materials, superior to the original ones, using more efficient conductors or refrigeration systems optimized for operation at high temperatures and low noise, are some examples.

Transformers with vegetable oils

In electricity networks, EDP has been reducing the production of hazardous waste by replacing mineral oils in transformers with vegetable oils, as it is a less environmentally damaging element.

All purchased transformers have plant ester as dielectric material, a compound is obtained from seed oil. The vegetable ester is a recyclable material, with

Collaboration is at the heart of our circular economy approach. We work closely with communities, suppliers, NGOs, and industry experts to understand their needs and share knowledge. By participating in collaborative platforms, we stay aligned with best practices and identify opportunities to improve resource efficiency and reduce environmental impact.

Partnerships strengthen our commitment to circularity. Through enhanced supplier assessments and sustainable practices across the supply chain, we embed circular principles in sourcing, production, and end-of-life management of materials and equipment. These efforts ensure that every stage of our operations contributes to a more sustainable future.

Joining industry initiatives, forums and pilot projects with partners

- Partnership with SOLARCYCLE in the US, to recover solar panels and other waste.

- Collaboration with Thermal Recycling of Composite (R3FIBER), RECICLALIA, and the LIFE REFIBRE project in Spain to recover wind turbines.