EDP is accelerating decarbonization towards 100% green generation by 2030. Thermal power stations in Spain, Portugal and Brasil, which have supplied populations and industries for decades, will now be key to ensure the energy transition.

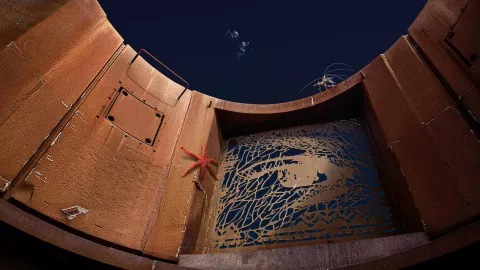

On the Albufeira seabed, a metal tower is home to fish, corals and a multitude of other organisms that give life to a new reef, a new ecosystem. The former coal mill of the Sines Thermoelectric Power Station, part of the EDP Art Reef, underwater exhibition created by the artist Vhils in partnership with EDP, is a small example of how the coal-fired power stations of the past have an important say in the future of energy and the planet.

This is the path that is being set by EDP, which aims not only to eliminate coal by 2025 and becoming 100% renewable by 2030, but also to turn these historic energy generation sites into incubators for new sources, new processes to ensure sustainability and the complete energy transition. Because we choose Earth, where there was coal, there will be green hydrogen, solar power, small hydro plants, energy storage batteries and forests, transforming thermal power stations from Portugal, Spain and Brazil into green hubs in their regions and countries. This year, EDP expects only 1% of its energy production to come from coal.

Four plants in Spain - Soto de Ribera and Aboño, in Asturias; Puente Nuevo and Los Barrios, in Andalucía; two in Portugal - Sines, in the district of Setúbal, Carregado, in the district of Lisbon; and part of the Pecém Plant, in Brazil, are fundamental axes of this process of transformation and revitalization of energy production. They represent an important share of the 17 billion euros to be invested by EDP up to 2026 in the development of projects to launch, expand and consolidate renewables and networks. All of this to guarantee the energy transition, the flexibility of electricity systems and the stability of the grids, while prioritizing the planet.

How do you decommission a thermal power plant?

The process of closing and decommissioning a power plant is long and meticulous. It begins with a request to the regulatory authorities and ends when the land on which the plant was installed is requalified and available for new uses.

- Decommissioning. The removal of chemicals, fuels, oils, gases and all other consumables from the production chain that can be easily transported. This phase can be preceded or accompanied by the removal of small equipment, furniture and materials that can be reused in other EDP production centers or even other industrial facilities.

- Dismantling and demolition. The dismantling of equipment for scrap recycling, from machinery to pipes and tanks. And the careful demolition of all structures, or those that cannot be reused, such as chimneys, cooling towers or turbines and generators.

- Requalification. Decontamination and environmental verification of land and other structures so that they can be safely used for new purposes, whether industrial, urbanization, agriculture or renaturalization.

The decommissioning of a thermal power plant is carried out by teams specialized in the various phases and by an on-site team, who truly has the experience and in-depth knowledge of the site, of the changes made over the years and of all the constraints that may exist.

And the communities that have been supported and benefited over the decades by the operation of these thermal power plants - whether through local economic development and employment, or through social, sporting or cultural initiatives supported by EDP - are also an important part of the transformation process. After closure, the transfer of equipment resulting from decommissioning to local entities; the continuity of community programs - such as Entama, in Spain, or Sharing with Energy and Used Car Donation Program, in Portugal; and the creation of specific projects to support closure - such as the Sines' Active Future program - are all part of EDP's overall strategy for a fair energy transition, leaving no one behind.

Circular economy: securing the value that still exists in a closed power plant

The end of a fossil fuel power plant, for the sake of the environment and the energy transition, does not mean that everything associated with that site and generation process should be eliminated or forgotten. There is a lot of value in a decommissioned thermal power plant, tons of waste and materials that can be reused; plenty of equipment with other possible uses; and infrastructure capable of hosting innovations, industries and technologies designed for a green future.

Thanks to the evolution of recycling and reuse techniques, and with a focus on the circular economy - which includes the use of materials in the EDP Art Reef, for example - EDP aims to achieve up to 90% recycling throughout the energy value chain. And the decommissioning of thermal power stations is at the forefront of this circularity journey. At the Carregado plant alone, for example, it was possible to recycle 92% of the 100,000 tons of waste collected during the dismantling and demolition phase.

EDP power plants: success stories on the road to a sustainable future

Between the sites that are already in a more advanced decommissioning process and those that will continue to operate until 2025 or a little beyond, EDP's power plants have their green path well marked. Below we detail the route that is already being taken by a total of nine plants in Spain, Portugal and in the particular case of Brazil. A path that branches out through the various renewable energy sources that make up EDP's portfolio, aimed at hybridization, energy storage and complementarity as ways of guaranteeing the solidity of each project and the entire power system, protecting local communities.

A portuguese example of environmental regeneration

The Carregado Thermoelectric Power Station, near Lisbon, was innovative for several decades until it was shut down in 2010. Of the 6 production groups powered by fuel oil since 1969, 5 and 6 switched to natural gas in 1997. It was the first power plant in Portugal to switch to this cleaner fuel.

With all the facilities now demolished, the vast area of the former power station continues the process of requalifying the land. Part of it is already in the soil study phase and can then be used for new projects. Before this, 92% of the approximately 100,000 tons of existing waste was recycled during demolition. And materials were reused for the nearby Ribatejo Combined Cycle Plant, the Belver hydro plant and the Mortágua biomass plant.

Support for local communities already existed and is still very much alive thanks to the Ribatejo Thermoelectric Power Station. From the old Carregado plant, kitchen equipment was donated to an institution in Vila Nova da Rainha and other items to the EDP Staff Club, which was opened in 1976.

A hub for green hydrogen in Portugal

When it began operating in 1985, the Sines Thermoelectric Power Station was capable of supplying 15% of the energy consumed in Portugal with two production groups, and rose to a third of the needs when it grew in 1987 to 4 coal-fired units, with a total capacity of 1,256 MW. The closure in 2021, two years ahead of schedule, effectively hastened the end of coal in Portugal's energy production.

The strategic position of the Sines plant, next to an important Atlantic seaport, makes it a unique location for the development of new green energy projects, particularly hydrogen. Now decommissioned, the plant is preparing for the first stages of dismantling, followed by conversion into an H2 hub. The GreenH2Atlantic project involves EDP and several other companies from the energy sector.

The end of operations at Sines has allowed equipment to be reused for thermal and hydroelectric plants in Portugal, Spain and Brazil, as well as for external entities. In all, over 6,000 pieces of equipment, weighing more than 370 tons, plus metal parts used by Vhils in EDP Art Reef. 10,000 tons of coal waste were also sold for fuel and 1.2 million tons of slag and ash will be reused in cement production. EDP Geração's strong integration into local communities has also made it possible to support 33 organizations and institutions with materials.

The last fuel oil plant

The Setúbal Thermoelectric Power Station was the most important in Portugal until the start of Sines, supplying up to 25% of the population, and the last to run on fuel oil. It was the first power station in Portugal to have its environmental management system certified by an external body.

Operations in Setúbal closed in 2013, after 35 years of activity, and the two chimneys over 200 meters high that marked the landscape were taken down in 2020. It has now been completely demolished, opening up various possibilities to use the space for new projects.

As in Carregado, in this plant it was also possible to recycle almost all of the waste accumulated during the dismantling and demolition phase: 92.6% of the 104,000 tons. Before that, some equipment had already been reused, such as firefighting equipment, which was given to the Setúbal fire department and sappers. Other production equipment was also sent for EDP's Sines, Ribatejo and Lares power stations, as well as for Tejo Energia.

The energy of the Algarve

Along with Carregado, the Tunes Thermoelectric Power Station, in Silves, was the longest in operation for EDP, between 1973 and 2014. Powered by diesel, it guaranteed energy for the Algarve region for 41 years, with an installed capacity of 165 MW at the time of its closure.

After the plant's dismantling and demolition phase, the administrative and workshop buildings were kept for future use, and the soil study phase is underway. Its smaller size, combined with the fact that part of the structures remained, led to less waste being produced during dismantling, around 5,000 tons, with a recycling rate of 57%.

Much of the equipment could be reused at the Mortágua plant, and some was sold to external companies, such as the rotors of turbines 1 and 2, and the exciter of group 3, a generator part that was bought by a Chilean company for replacement. The region's firefighters were also given firefighting equipment.

Asturias' green battery

With 3 coal-fired generation groups and 2 combined cycle units, the Soto de Ribera Thermal Power Station, near Oviedo, began operating in 1962. It keeps the three most recent units in operation and is preparing to decommission group 3, which is still coal-fired, in 2025. Soto 1 has already been decommissioned and Soto 2 is in the final stages of dismantling, both of which are preparing to receive the first renewable projects, very much focused on energy storage and hybridization.

At the Asturias green battery, a mini hydro plant and a photovoltaic park will be used to supply energy to the grid, but also to store it in lithium batteries and in a combination of RedOX batteries and other second-life batteries, such as those from electric vehicles, as well as testing storage using liquid air. At the same time, a 5 MW electrolyser will produce green hydrogen to fuel vehicles and promote the decarbonization of transport, in addition to being used in the plant's combined cycle groups associated with natural gas.

Some of the old equipment was used in the Vhils project, and other more recent materials are being reused in other sectors. Part of the group 3 facilities will remain to accommodate new projects. Local cooperation with the municipality of Ribera de Arriba goes back more than half a century and culminated in 2023 with the inauguration of the Central Artística de Bueño, a major cultural development project supported by the EDP Foundation.

The green hydrogen valley of Asturias

At the gates of Gijón, the Aboño Thermal Power Station, with two production groups, has been essential for decades in supplying energy to the entire region. Group 1 is set to be decommissioned in 2025, currently remaining only as support, and group 2 will be converted from coal to natural gas, in the context of a partnership between EDP and the Masaveu group. The green hydrogen valley will be a catalyst hub for EDP's various renewable projects in Asturias.

The Aboño plant will receive an electrolyzer system with a capacity of 150 MW, increasing to 500 MW in a second phase, starting in 2027, if market conditions are favorable. For the production and storage of green hydrogen, the electrolyzers will only be powered by renewable sources, namely through new solar and wind projects at the plant and in the region.

Green hydrogen can also be combined with steel gases that are already used at the plant, gradually replacing fossil fuels. Transforming the energy production also guarantees the use of a large part of Aboño 2's structures and equipment, ensuring a circular economy and just transition.

Andalucía's sun on the horizon

It was in 2020 that the last of the 3 production groups at the Puente Nuevo coal-fired power station in Córdoba - which began generating energy in 1966 next to a reservoir on the Guadalquivir River - closed down. Part of the plant has already been dismantled and work has begun to prepare it for the future, including the reforestation of an area of several hectares with more than 4,000 native plants.

Solar photovoltaics is the main focus for the green energy future of Puente Nuevo, with the installation of a 300 MW onshore solar park and an innovative 50 MW floating solar project on the reservoir.

After the closure of group 3 in 2020, various types of equipment were sent for use at other EDP plants, such as Los Barrios, also in Andalucía. Mainly boiler pipes, fittings, pumps and valves, but also 17 tons of metal balls for coal mills at the Aboño plant.

Green hydrogen in Campo de Gibraltar

Next to the bay of Algeciras, the Los Barrios Power Station will give way to the new green hydrogen valley of the Campo de Gibraltar, a 195 million euro project. The first coal-fired production group is already closed and the second one is only available until 2025, when new projects to help with the energy transition of the entire Cádiz region will be accelerated.

The two lines of action in the field of renewable energies are mainly green hydrogen and energy storage. As in Aboño, electrolyzers with a capacity of 130 MW will be installed in 2026, which may be increased to more than 500 MW depending on regional use by industries and transport, and the possibilities for export by sea. As for the lithium battery system for energy storage, it is set to have a capacity of 255 MW.

The decommissioning of the Los Barrios plant will make it possible to reuse several pieces of equipment and installations, including for the new projects. And the link with the local community of the same name will always be strengthened as part of a just transition. Campo de Gibraltar's green hydrogen projects will create jobs and boost the local economy with clean energy.

Where green hydrogen is already a reality

The Pecém Plant, part of the thermoelectric complex of the same name in the Brazilian state of Ceará, is another generation site that points the way to sustainability for EDP in the country and the world. At the end of 2022, EDP's first green hydrogen molecule, which is essential for the global energy transition strategy, was produced at this site.

In operation since 2012, 80% of the 720 MW coal-fired plant was sold in 2023 to a group of investors. The future will see the transition of production to other fuel sources, where green hydrogen can be integrated, ensuring even more clean energy in the region. The Nordeste already stands out in renewables, concentrating 82% of the national installed capacity of solar and wind energy.

EDP keeps the Pecém H2V project, which began as a pilot project with a capacity of 1.25 MW, at an investment of 7.5 million euros. The hydrogen electrolyzer module is powered by a 3 MW photovoltaic park. In addition to the large local industrial complex, Pecém has a sea port which, instead of receiving coal, might be able to transport green hydrogen to decarbonize other regions and countries.